VisionSpace, a developer of AI digital twin platforms for factory and logistics center automation, has raised pre-seed funding from 500 Global. The company was also selected for Deeptech TIPS, recognizing its innovative use of AI digital twin technology to enhance productivity and operational efficiency through the integrated control of industrial robots.

Deeptech TIPS is a program that accelerates global market entry for early-stage startups with groundbreaking technologies by providing R&D funding and networking support.

With automation rapidly advancing in the manufacturing sector, the demand for robots in factories and logistics centers is increasing. This growth has also driven demand for integrated control software, such as Robot Operating System (ROS)-based Robot Management Systems (RMS), Automated Control Systems (ACS), and Execution Control Systems (ECS).

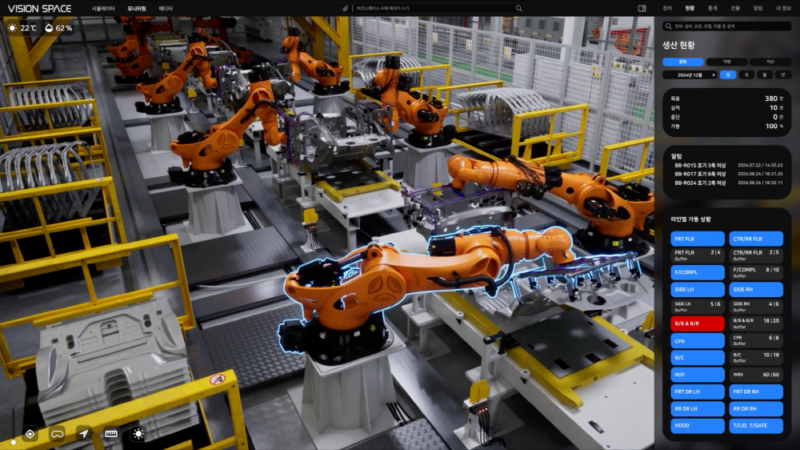

To address these needs, VisionSpace has developed a proprietary automation engine that combines AI with digital twin technology. Using RAG-based LLM/VLM AI, the company provides a 3D generator and editor to create diverse virtual simulation environments and efficiently simulate 3D robot models. By leveraging real-time data, VisionSpace’s control system optimizes robot movements and paths, enabling remote workflow and logistics management to boost productivity while reducing costs.

Hyuk-hyun Kwon, Investment Manager at 500 Global, stated, “VisionSpace has harnessed Korea’s robust manufacturing foundation and advanced robotics ecosystem to achieve global competitiveness. Korea’s status as the world leader in robot density is a significant asset in high-tech industries. VisionSpace’s technology offers unparalleled value in the global automation market.”

Wonseok Choi, CEO of VisionSpace and a former Hyundai Motor researcher with over a decade of experience, commented, “This funding and our selection for Deeptech TIPS validate VisionSpace’s technological capabilities and market potential. By integrating industrial robots, AI, and digital twin technology, we aim to set new standards in automation, maximize efficiency and productivity, and accelerate the advent of the Industry 6.0 era.”

MORE FROM THE POST

- ROAI Secures USD 1 Million Seed Funding to Develop AI-Powered One-Click Smart Factory

- Magnendo Gains Backing from BASS Ventures, Kakao Ventures for Robotic Brain Neurotherapy

- The Invention Lab Completed pre-Series A investment for FutureGate and dSPECTER

- Index Robotics Raises $1M Seed Round to Deploy Humanoid Robots on the Factory Floor

- MEDISBY Secures Seed Funding to Advance AI-Powered Rehabilitation Robotic Arm and Global Expansion

- 500 Global

- Deeptech TIPS

- Digital Twin

- EN

- factory automation

- funding

- Korea

- Korean startup

- pre-seed

- robotics

- TIPS

- VisionSpace

Share

Most Read

- 1

- 2

- 3

- 4

- 5

Leave a Reply