“AI” and “robotics” are inescapable keywords when discussing the future, poised to transform every aspect of daily life. In manufacturing, they promise a revolution as profound as any in industrial history. ROAI, a startup spun off from Hyundai Motor Group in February 2025, has entered the industrial robotics market to lead this transformation. Aiming to develop AI robotics solutions for industrial robot planning, what future does ROAI envision?

ROAI’s core service concept is the “One-Click Factory,” a technology that automates the entire manufacturing process—from production planning to robot operations—with a single button click, maximizing efficiency.

Traditional manufacturing relies on manual validation and trial-and-error by skilled engineers, leading to inconsistent quality, lengthy review times, and high costs. ROAI seeks to overcome these limitations by developing AI robotics solutions that autonomously control robots from production planning to individual motions, eliminating human error.

To achieve this, ROAI first digitizes fragmented manufacturing data, then uses a proprietary AI engine to generate optimal production processes and robot motions. The AI algorithm performs thousands of calculations to identify processes that enhance efficiency, surpassing human capabilities and delivering performance improvements of 10–15% over expert work.

ROAI’s solution modularizes the automation process, connecting each stage via pipelines to automate everything from production planning to generating robot programs for factory operations. Unlike competitors focused on specific automation tasks or labor replacement, ROAI’s comprehensive approach to entire manufacturing processes sets it apart.

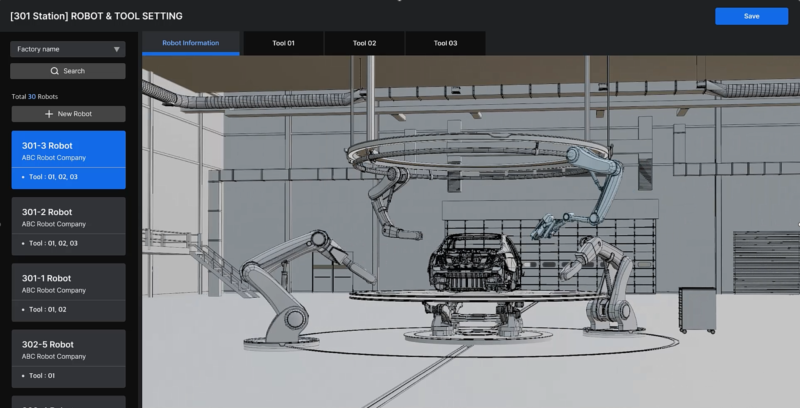

Founder and CEO Seokui Hong declared, “We’re creating a future where a factory starts with one click. Our AI engine and web workspace enable customers to easily design factories, input product details, and generate collision-free robot motions.” Customers can set up factories in the web workspace, placing robots and tools, and entering product information and task targets. The current solution, at 80% completion, is preparing for a beta launch in the second half of 2025.

ROAI targets the industrial robotics market, where over 600,000 units are deployed annually, valued globally at USD 43 billion (KRW 60.2 trillion) with a projected 7% annual growth. ROAI has validated its technology through proofs of concept with Hyundai Motor and Kia, focusing on complex automotive bodywork processes, and plans to expand to domestic and international automotive OEMs, as well as assembly and measurement industries. Notably, pilot projects at Hyundai’s Ulsan and Singapore factories demonstrated a 13% reduction in production time compared to human efforts.

ROAI’s greatest strength is CEO Hong’s leadership, rooted in manufacturing plant experience. Without a deep understanding of production processes, AI and robotics alone cannot deliver complete services. ROAI’s expertise in manufacturing digitization makes it stand out.

With global first-mover advantage, a three-year technological lead, rising robot adoption due to labor shortages, and a highly efficient expert team, ROAI recently secured USD 1 million (KRW 1.4 billion) in seed funding, proving its vision is no mere promise. The company plans to bolster its capabilities by hiring digital twin and 3D web service specialists with this investment.

What problem is the ROAI team trying to solve?

Current manufacturing relies on manual validation for designing and operating automated production lines. Skilled engineers’ trial-and-error processes result in inconsistent quality, long review times, and high costs. We believe manufacturing should become a “One-Click Factory.”

The One-Click Factory automates programming and production with a single click, requiring autonomous robot control technology unattainable with human-dependent methods. We’re developing AI robotics solutions to automate production planning and individual robot motions.

How do we solve this problem?

We’re advancing robot automation in manufacturing through two approaches.

First, we digitize fragmented manufacturing data, enabling AI to derive optimal production processes. Understanding the industry allows us to define digitization’s scope and methods, a strength of our team’s dual expertise in AI and manufacturing.

Using ROAI’s AI engine, we fully automate manual tasks previously reliant on trial-and-error. Our algorithms perform thousands of calculations to find processes that outperform human limits, consistently achieving 10–15% performance improvements over expert work.

What are ROAI’s competitive advantages and technical strengths compared to competitors?

Our core AI engine is our primary strength, modularizing manufacturing automation and connecting stages via pipelines to automate planning through to robot programming. Globally, we’re the only company automating at this data scale. While competitors in robot motion planning exist, our integration of robotics and manufacturing automation gives us a broader edge.

This technology requires manufacturing expertise and production experience, refined through on-site feedback. We’ve been applying and enhancing our algorithms for two years, now tackling projects that replace human labor. Our experience-based algorithms and capable team are our competitive advantage.

What products/services does ROAI offer, and what is their current status?

We provide an AI engine for manufacturing challenges and a web workspace for easy engine operation and cross-departmental collaboration. Customers can set up factories, place robots and tools, and input product details and task targets in the workspace.

Input data is stored as digitized datasets suitable for AI computation, aiding customers’ digital transformation. Unlike simulation software requiring manual robot operation, our workspace generates optimal robot motions and collision-free paths by simply specifying task coordinates.

Our service is 80% complete, with a beta version set for launch in the second half of 2025.

What is the target market size, and who are the core customers?

Our market encompasses all industrial robot deployments, with over 600,000 units annually and a 7% yearly increase. Assuming a 10-year robot lifespan, we target programming for about 430 units.

We’ve developed technology for complex automotive bodywork plants, validated through Hyundai/Kia PoCs. This is our strongest domain, and we plan to expand to domestic and global automotive OEMs, while also targeting assembly and measurement industries.

What is our business model?

Short-term, we automate robot planning simulations; long-term, we automate on-site robot operations, charging based on the number of robots deployed.

While exact pricing is TBD, our automation cuts planning costs by 50% and reduces timelines by over 90% compared to human services.

As the market isn’t fully convinced of AI, we’ll operate a contract model, managing data setup to system operation, and a plan model, licensing our workspace and AI engine.

What are our team’s achievements?

Our greatest achievement is proving AI can automate manufacturing with higher quality than humans in a conservative industry. Initially, the market believed manufacturing AI couldn’t replace humans, only assist, due to complex rules and domain knowledge.

Over the past year, we applied our technology at Hyundai’s Ulsan and Singapore Innovation factories, achieving cost/schedule reductions and a 13% average production time improvement over human results.

What is the ROAI team’s competitiveness?

Only CEO Hong comes from manufacturing. The mature automation industry, developed over 20 years, is rigid with established software, robot operations, and stakeholder interests, making paradigm-shifting innovation challenging.

Hong recruited AI and robotics talent, providing manufacturing domain knowledge to create automated software. This diverse team tackles problems with fresh perspectives, focusing solely on industry innovation without legacy constraints.

Why should we receive investment? Three reasons!

First, we’re the global first to reach commercialization, applying technology faster than competitors and refining it with feedback, maintaining a three-year lead.

Second, the manufacturing AI industry will grow as robot adoption rises and skilled labor dwindles. Companies face complex operations and costs, making AI adoption inevitable, a major opportunity for ROAI with early market experience.

Third, our compact team of top AI/robotics talent achieves complex development with half the typical headcount, proving our ability to solve tough problems efficiently. We’ll hire digital twin and 3D web experts to enhance competitiveness, poised for greater synergy.

MORE FROM THE POST

- [Korean Startup Interview] AETECH’s AI-Powered Robots: Transforming the Global Recycling Industry

- [Korean Startup Interview] StepHow, Revolutionizing Workplace Efficiency with AI-Powered Manual Automation

- [Korean Startup Interview] BeringLab: “Expanding Globally with Specialized AI Translation for Law, Patents, and Clinical Fields”

- [Korean Startup Interview] Deepvisions: Revolutionizing Air Pollution Monitoring with AI-Powered Vision Technology

- [Korean Startup Interview] From Text to CAD: How Herewe’s EaseAI Is Revolutionizing Product Design

- AI

- automation

- factory automation

- Interview

- Korea

- one click factory

- ROAI

- robotics

- smart factory

- Startup Together

- wow together

- WOWTALK

Leave a Reply