The cost of clothing continues to rise every year, but the labor costs and profits of clothing manufacturers have seen little change. This is because the productivity of garment manufacturing has lagged behind the rapid advancements in the fashion industry. However, automating garment manufacturing is no easy task. Due to the soft and flexible nature of fabrics, it is difficult for machines and robots to accurately identify the exact shape of garments, making precise automation challenging.

But there is potential for significant productivity improvements if manufacturers can accurately monitor sewing processes down to the level of individual machines, predict production volumes, order materials accordingly, and quickly establish production plans. One company working to make this a reality is ‘SIJE.’

SIJE was founded in May 2021 by CEO Shin In-joon, who studied Clothing and Industrial Engineering at Hanyang University. Shin worked at a women’s apparel vendor, where after just three years, he became head of the ‘Process Analysis Center.’ Through extensive experience at overseas production sites, he dramatically improved productivity, which led him to establish SIJE.

SIJE’s method for predicting and enhancing productivity is both simple and innovative. The company has developed two key products: ‘Monolog,’ a data collection device, and ‘Monolis,’ a software program that analyzes production data and forecasts output.

Monolog is a sensor device attached to sewing machines. It rapidly collects vibration data from the machines at a rate of 30 pieces per second. In simple terms, it monitors the amount of vibration data generated to identify which production lines are slowing down and which workers are performing most efficiently. It can also measure electricity consumption, which is another indicator of productivity. Additionally, by pressing a button each time a garment component is produced, Monolog tracks production volumes in real time, allowing for more accurate forecasting. This helps optimize the timing of material orders, further improving efficiency.

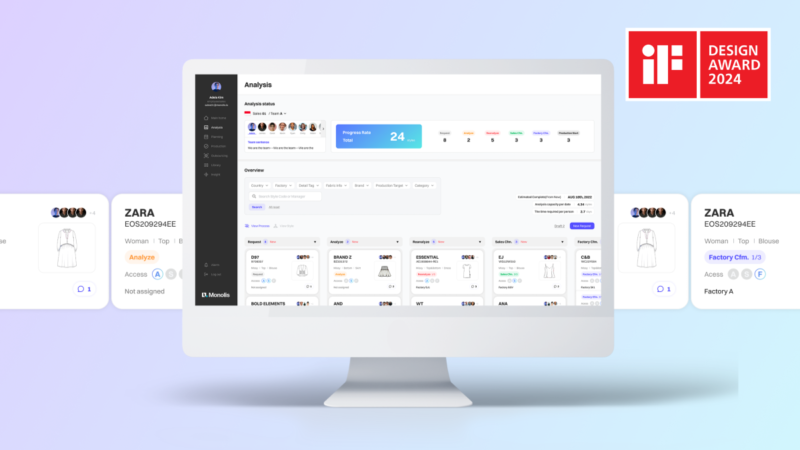

Monolis is an analytical solution that uses the data collected to offer insights into improving productivity. It helps identify bottlenecks in production lines, determine where to allocate more resources, and analyze which workers deserve higher compensation. Through this analysis, garment manufacturers can enhance their productivity.

Shin’s experience working in overseas production sites played a crucial role in SIJE’s development. By analyzing productivity through machine vibrations and power consumption data, he has provided garment manufacturers with clear, actionable insights.

Recognizing SIJE’s potential, one of Korea’s leading apparel trading companies, Y Company, has partnered with the startup to introduce Monolog and Monolis into their factories in Vietnam. They are also preparing to expand to other traditional garment-producing countries like Indonesia and Bangladesh.

Since its founding in May 2021, SIJE has achieved several milestones. In 2022, the company won the Minister’s Award in the Data Voucher category from the Ministry of Science and ICT, was selected for the TIPS program in 2023, and in March of this year, received the prestigious iF Design Award in Germany.

As a part of the ‘Youth Overseas Expansion Support Program’ hosted by the Incheon Center for Creative Economy & Innovation, SIJE is working on expanding internationally. They raised seed funding in 2022, secured pre-Series A funding earlier this year, and are preparing for Series A funding in the first quarter of next year. CEO Shin has expressed a strong commitment to global expansion, saying, “From Series A onwards, we plan to seek investment primarily from foreign investors.” If SIJE achieves its goals, it will serve as a prime example of a CEO who has meticulously analyzed an industry and turned that insight into a thriving business.

What problem is SIJE aiming to solve?

Garment manufacturing has struggled to standardize and streamline production due to the inherent flexibility of fabrics, leaving the industry highly labor-intensive. Even if advanced robotic arms with thousands of sensors and joints are developed in the future, they will likely be cost-ineffective compared to the labor in developing countries. Moreover, the software to control such robots would need to be developed first.

While companies like Tesla and others in the robotics industry are developing jointed robots capable of garment production, SIJE aims to solve the challenge of implementing an autonomous manufacturing system for the apparel industry.

How is SIJE solving this issue?

SIJE offers a SaaS solution that integrates the physical production floor with a virtual layer of data and software. To collect real-time production data, we’ve developed IoT devices that connect to a cloud server, allowing seamless communication with our software. This system enables easy access to real-time production information from any location, allowing factories to be managed remotely through digital twin technology without the need for on-site supervisors.

What sets SIJE apart from its competitors in terms of technology and competitiveness?

Our competitive edge lies in real-time data processing, AI-based process analysis, an RPA sourcing system, and the EASI system.

First, our real-time data processing technology categorizes data from IoT devices within 0.1 seconds for use in both learning and visualization, sending it to the appropriate server. The learning data is used by our AI-based process analysis module to simulate manufacturing processes and predict production volume and costs, providing critical information for accurate production planning.

Second, our RPA sourcing system automates over 90% of sourcing tasks, from material orders to international trade operations, simply by uploading the work order, significantly reducing the workload of traditional sales staff.

Third, SIJE’s EASI system is Essential, Affordable, Simple, and Interoperable. It offers essential features at competitive prices, is easy to use, and provides excellent compatibility with other solutions. These technological advantages allow customers to quickly understand and use our solutions without in-depth training.

In summary, our solution combines efficiency, precision, and user-friendliness, giving us a strong advantage over our competitors.

What products and services does SIJE offer, and what is their current status?

We offer smart solutions and devices to revolutionize garment supply chain management.

First, ‘Monolis’ is a SaaS manufacturing program that uses big data to predict production volume and costs in the apparel industry. This solution moves beyond traditional methods like manual tracking, Word, or Excel, applying AI-powered RPA modules to enable fast and accurate decision-making.

Second, ‘Monolog’ is an IoT-based production tracking device installed near sewing machines that measures real-time data such as vibration frequency and electricity usage. This data allows precise analysis of production volume and efficiency across lines and processes, providing a detailed understanding of production performance.

Third, ‘MoAI’ is an LLM-based AI designed for big data analysis in garment productivity. It statistically analyzes variables in production, becoming more accurate over time and achieving over 95% precision in productivity forecasts.

All of these products have completed their development and successfully passed proof-of-concept (PoC) tests.

What is the size of SIJE’s target market and who are its core customers?

Globally, there are approximately 150,000 garment factories and 35,000 apparel trading companies, with the market valued at around $2 trillion. While our solutions can serve brands (buyers), trading companies (intermediaries), and factories (suppliers), our core target customers are apparel trading companies, which serve as the supply chain’s backbone by operating their own factories in developing countries to reduce labor costs.

What is SIJE’s business model?

Our business model consists of installation fees, device sales, monthly subscription fees per account, and charges for data analysis and AI modules.

For instance, a trading company with about 500 employees would generate subscription revenue of approximately 12 million won per month by using Monolis, while a factory with 1,000 employees would generate about 200 million won in revenue in the first year of installation.

What has SIJE accomplished so far?

SIJE secured seed funding in 2022 and seed bridge funding in 2023, raising 2 billion won in pre-Series A funding earlier this year. The company has received awards such as the Minister’s Award from the Ministry of Science and ICT, the Minister’s Award from the Ministry of SMEs and Startups, and the iF Design Award in 2024.

We have signed a pilot contract with Y company, Korea’s leading apparel trading company, to install our solutions at their Nam Dinh factory in Vietnam in the second half of this year. Additionally, two technology patents have been registered, PCT applications have been filed, and eight trademarks have been submitted for international Madrid filing.

What are SIJE’s competitive strengths?

Our service planning team consists of experts with over 10 years of experience working at apparel trading companies, all serving as project managers (PMs). Our development team is split into SaaS and IoT teams. The SaaS team includes professionals with extensive MES and ERP development experience, while the IoT team includes specialists who have collaborated with companies like Wooree Technology, LG, and LS.

Why should investors choose SIJE?

First, we plan to develop 3D technology to further enhance our digital twin solutions. Once implemented, this technology will allow remote factory management from corporate offices, significantly reducing the costs of mid-level supervisors.

Second, building on our AI process analysis technology, we aim to develop an LMM-based AI for autonomous manufacturing. This technology will enable production simulation, helping prevent accidents and defects while identifying and addressing productivity bottlenecks, maximizing profits for companies.

Third, we are poised to shift the current offshoring trend, where production moves to developing countries for cheaper labor, by offering a reshoring solution that enables low-cost production even in developed nations. This has the potential to revolutionize the garment manufacturing paradigm and position SIJE as a leader in the global apparel industry.

What efforts is SIJE making for global expansion, and what are the results?

We have already entered the Vietnamese market and plan to expand into Indonesia and Bangladesh. In Vietnam, we have established a corporation in Hanoi to support Y company and will use this as a marketing base to secure additional clients.

Our software is primarily in English but is also available in Korean, Vietnamese, Malay-Indonesian, and Bengali, allowing for smooth expansion into target markets.

How has the Youth Overseas Expansion Program supported SIJE’s global growth?

After establishing our Vietnamese corporation, we received a variety of consulting services to stabilize its operations. We are also receiving consultations on securing additional investment from foreign investors for our next round of funding.

MORE FROM THE POST

- [Korean Startup Interview] ROAI Launches AI Robotics to Revolutionize Manufacturing with One-Click Factory

- [Korean Startup Interview] HOW3, Pioneering Virtual Music Characters in Global Digital Content Market

- [Korean Startup Interview] From Text to CAD: How Herewe’s EaseAI Is Revolutionizing Product Design

- [Korean Startup Interview] HYUNSUNG, “Revolutionizing Global Logistics with Smart Labels and AI-Powered Platforms”

- [Korean Startup Interview] AETECH’s AI-Powered Robots: Transforming the Global Recycling Industry

- AI Solutions

- Apparel Manufacturing

- automation

- Data Analytics

- FashionTech

- go global

- Interview

- IoT

- Korean

- Korean startup

- Productivity

- sije

- smart factory

Share

Most Read

- 1

- 2

- 3

- 4

- 5

Leave a Reply