AI semiconductor production lines are accelerating the transition to 12-inch (300mm) wafer processes due to the recent expansion in demand for HBM (High Bandwidth Memory) and GPUs. With process miniaturization and advanced packaging technologies, production yields have reached a stage where they are affected by temperature changes of 1°C, vibrations of 0.1G, vacuum level variations of 0.01~0.1 Torr, and plasma power fluctuations of several watts.

Accordingly, semiconductor fabs collect real-time data from production lines using Wireless Sensor Wafers to manage process stability. The problem is that the power technology operating these sensors has remained virtually unchanged for decades.

Wired power sources can cause process contamination through cable vibrations, power outage risks, and particle generation, while conventional batteries are unsuitable for process environments in terms of high temperature, high vacuum, EMI, and cleanroom compatibility. In other words, while sensor technology has advanced, ‘power’ remained the last frontier left as a void.

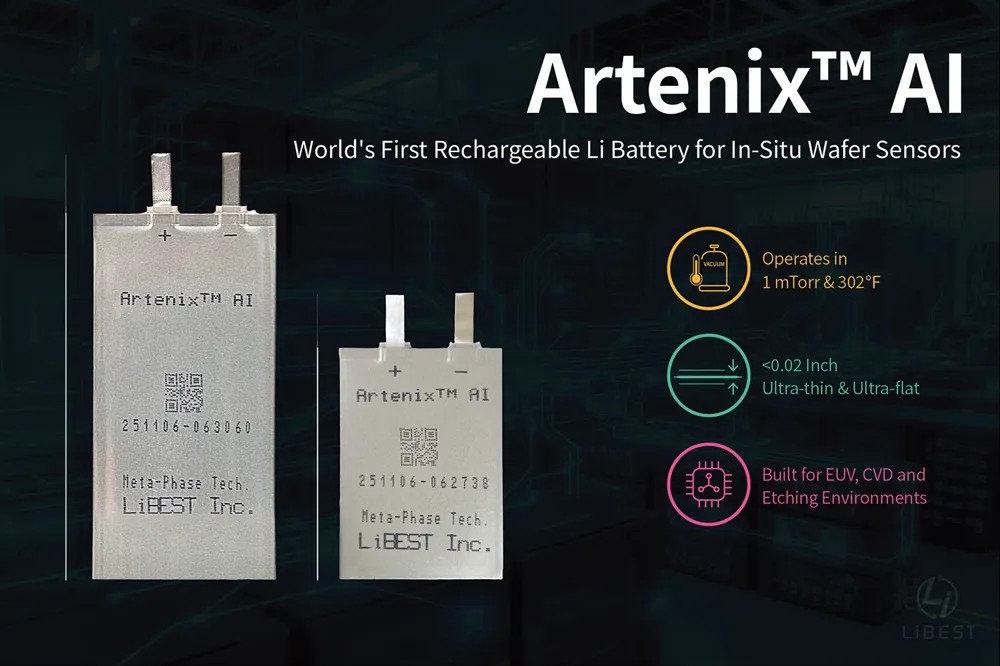

LiBEST‘s ‘Artenix AI’ is the world’s first process-specialized battery technology targeting this gap. Through gas-free, dust-free, and high-temperature resistant material design, it responds to cleanroom environments and enables stable power supply even under high temperature, high vacuum, EMI, and precise vibration conditions. The key differentiation is that unlike existing batteries, it was designed considering the physical, chemical, and electronic environments of semiconductor processes.

Juseong Kim, CEO of LiBEST, stated, “In the AI semiconductor era, what’s more important than sensors is the power that ‘brings sensors to life.’ This area has been the last gap that no one has paid attention to until now.” He added, “LiBEST’s goal is not to sell batteries, but to create standards for the AI manufacturing ecosystem.”

Semiconductor industry experts note that this award could signal the start of competition for global semiconductor process power technology standardization.

Currently, KLA maintains a monopolistic position in the process monitoring wafer market after acquiring SensArray, but no standard alternative technology exists in the power field outside of KLA. As AI semiconductor demand increases and the demand for wireless sensor wafer markets for process monitoring expands, these specialized batteries could be directly linked to semiconductor supply chain dominance as a power standard for wireless sensor wafers.

CEO Kim added, “AI semiconductors are directly connected to national competitiveness. Power technology that determines process stability will become a strategic technology in the semiconductor supply chain.” He continued, “We wanted to prove the possibility that Korean technology can enter the core layer of global semiconductor processes. The CES award is the first signal to widely publicize that technology.”

LiBEST plans to formalize technology collaboration discussions with global foundries, OSATs, and equipment companies at CES 2026. As it is unusual for a startup to enter the semiconductor process infrastructure layer, its future moves are expected to become an industry litmus test.

CEO Kim concluded, “A small technology that started in a Daejeon research lab is now solving problems in semiconductor factories around the world. The origin of technology doesn’t need to be Silicon Valley.”

LiBEST plans to accelerate expansion into global strategic markets including aerospace, defense, and AI semiconductors, while securing references for ‘Artenix AI’ following this CES Innovation Award.

MORE FROM THE POST

- StudioLab Wins Best of Innovation Award at CES 2026 in XR & Spatial Computing Category

- Gaudio Lab Secures Two CES 2026 Innovation Awards, Marking Fourth Consecutive Year

- Naver Cloud and Rebellion Sign MOU to Build Sovereign AI in Saudi Arabia

- Rebellions Expands Middle East AI Strategy as Aramco’s Partner at LEAP 2025

- Seoul AI Hub Showcases Korean AI Startups at CES 2025, Highlighting Innovation and Global Potential

Share

Most Read

- 1

- 2

- 3

- 4

- 5

Leave a Reply